Automotive Wire Harnesses Manufacturer Fast Prototypes, Traceable Tests

One engineering contact, multi-factory capacity, honest capability boundaries.

Compliance & Testing Standards

Certified quality across every dimension

Branded names for compatibility only (TE/Molex/JST/Aptiv/AMP+). Traceability: barcode + test data retention.

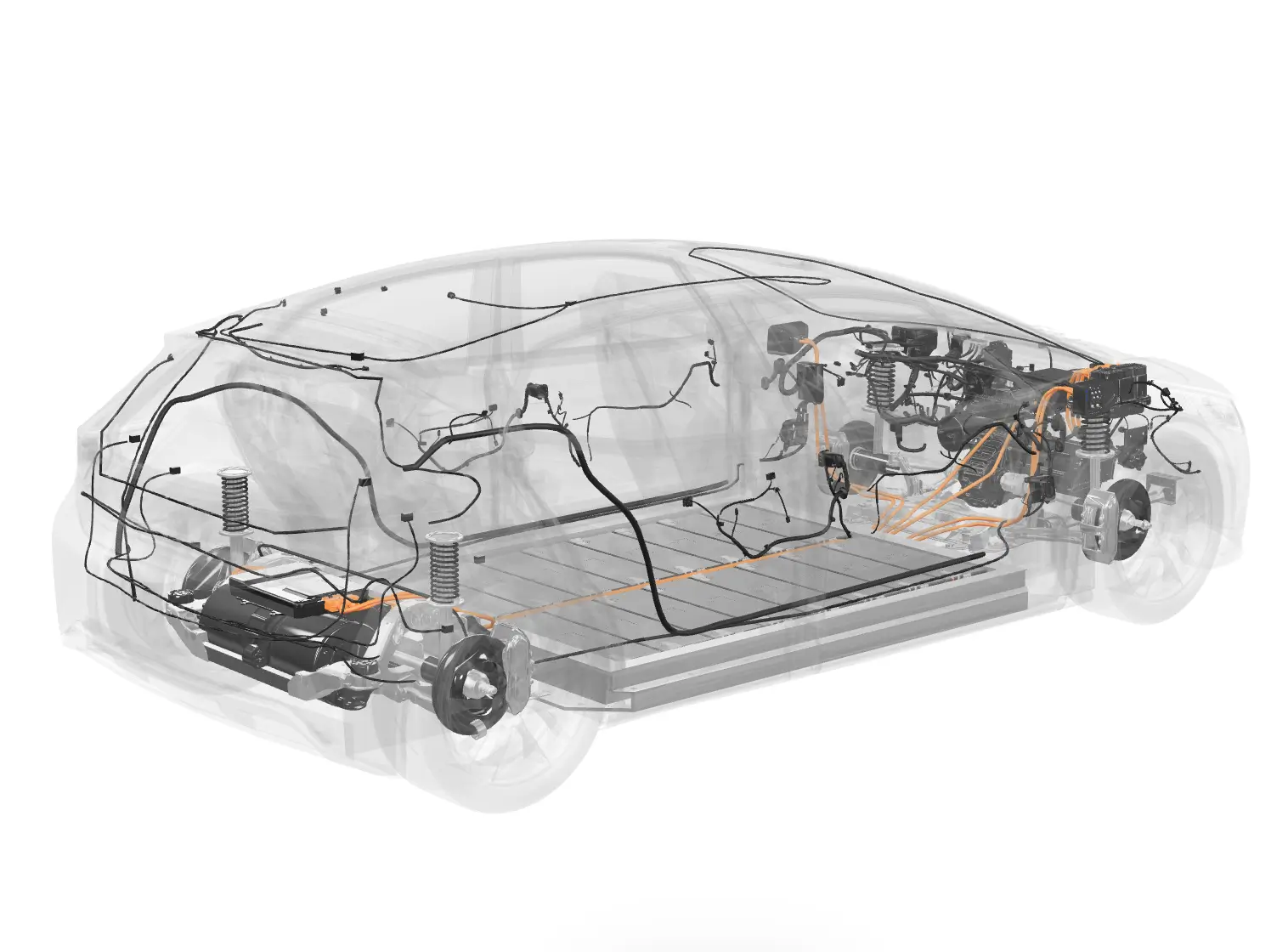

What We Make

Custom LV/HV harness solutions with precise specifications

LV Wire Harness

Low Voltage

HV Wire Harness

High Voltage

Testing & Compliance

Comprehensive testing protocols with traceable documentation

Continuity Testing

100% continuity testing up to 1024 points with automated test fixtures. Complete test data retention and traceability reports.

Hipot Testing

High voltage testing 0-1.5kV (F1) and 0-3kV (F2) per drawing specifications. Automated test sequences with pass/fail documentation.

| Test Item | F1 (LV) | F2 (HV) | Notes |

|---|---|---|---|

| Continuity | 100% (≤1024 points) | 100% | Final report |

| Hipot | 0–1.5 kV | 0–3 kV | Per drawing |

| Pull/Crimp | Pull gauge | + CFM monitoring | Records |

| Micro-section | Partner/External | In-house + partner | Report |

| Environmental | 3rd-party | 3rd-party (co-managed) | DVP&R |

| Acceptance | IPC-A-620 Class 2 | Class 2/3; CSR priority | Standard |

| Documentation | RoHS/REACH, reports | PPAP L2–L3, IMDS | Per project |

Note: Environmental/vibration/IP tests arranged with qualified partners. No in-house environmental/vibration/IP laboratory.

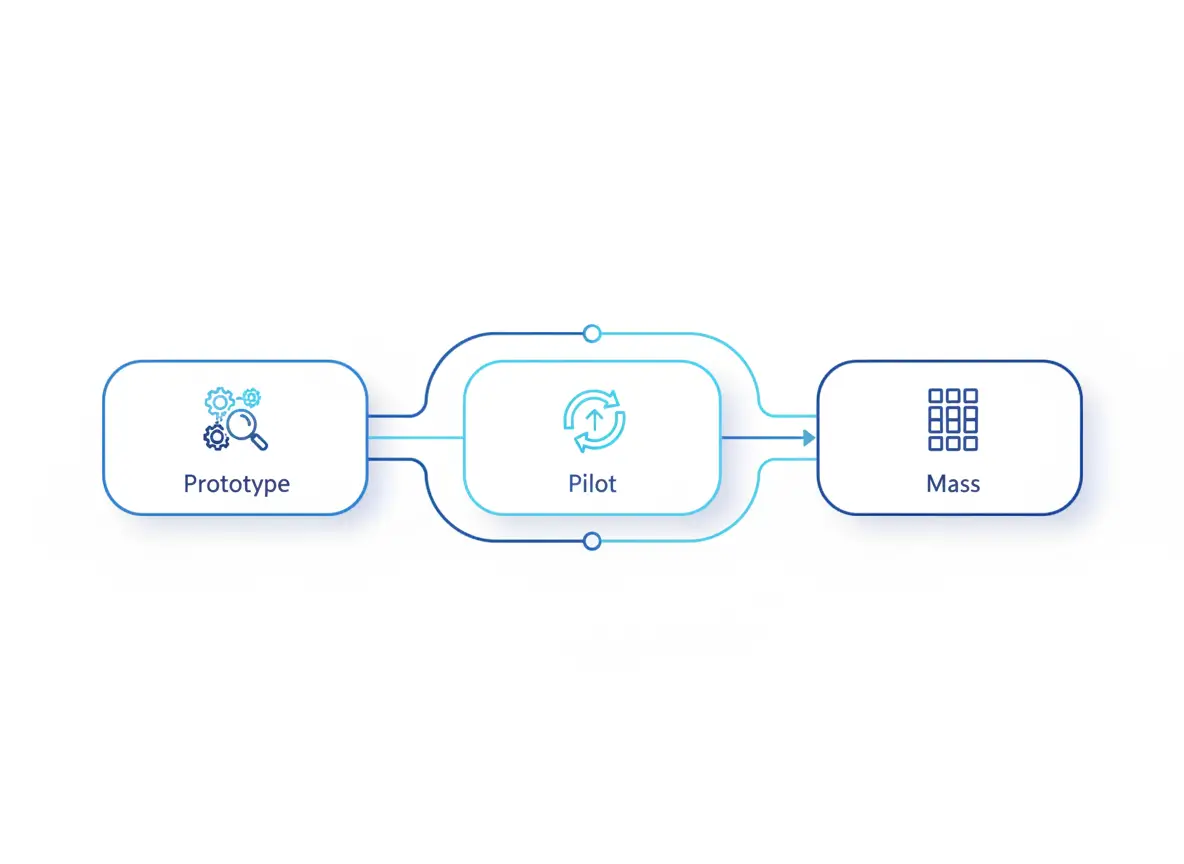

Delivery & MOQ

Flexible production schedules for prototype to mass production

F1 (LV) Timeline

Low Voltage Production Schedule

F2 (HV) Timeline

High Voltage Production Schedule

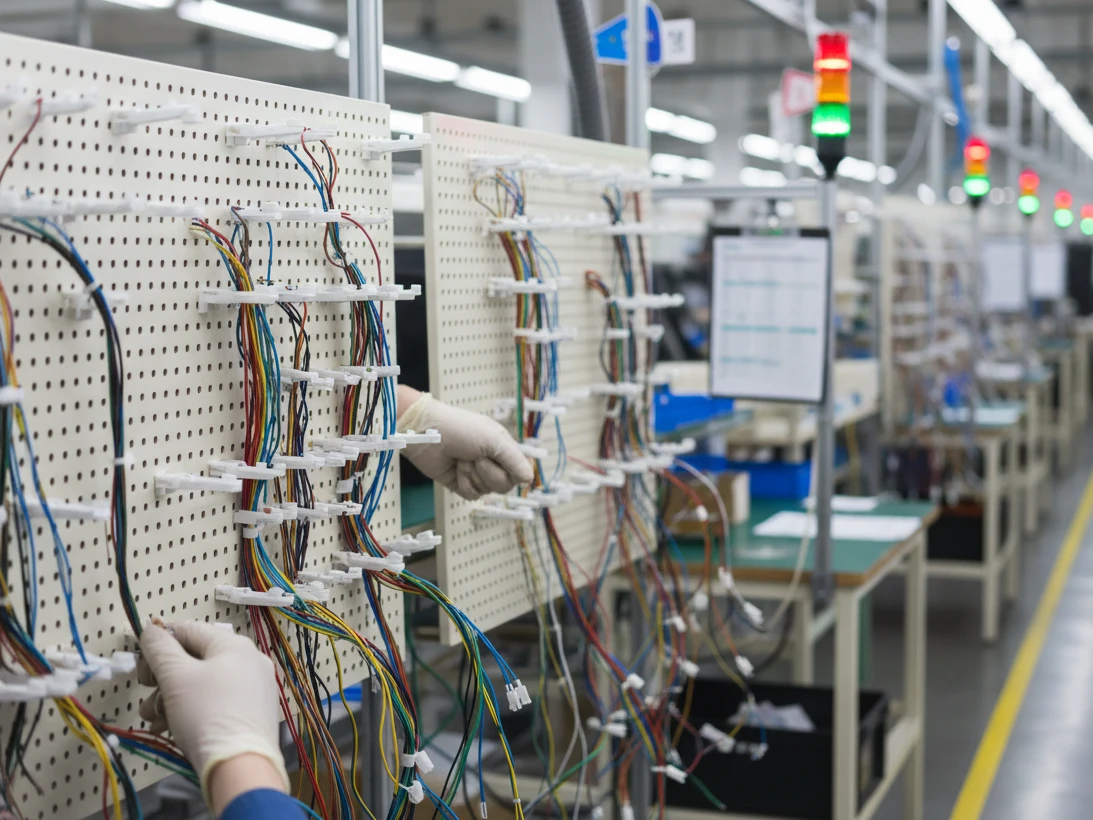

Manufacturing Showcase

From assembly to testing - precision at every step

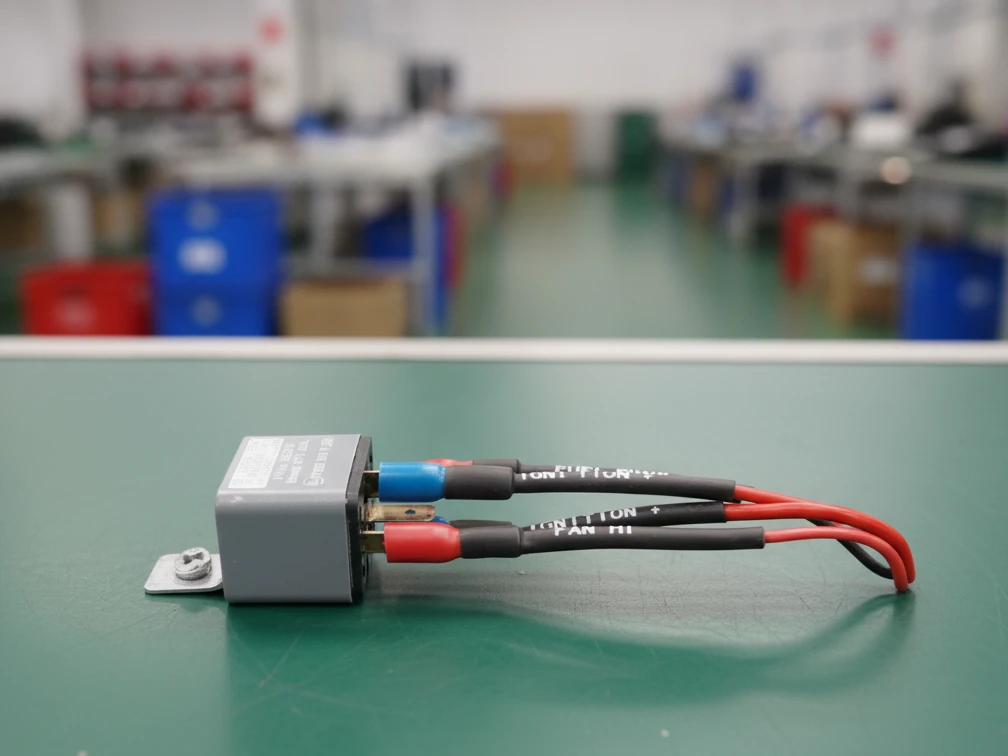

LV Assembly Line

Dedicated production lines for low voltage harness assembly with quality control stations.

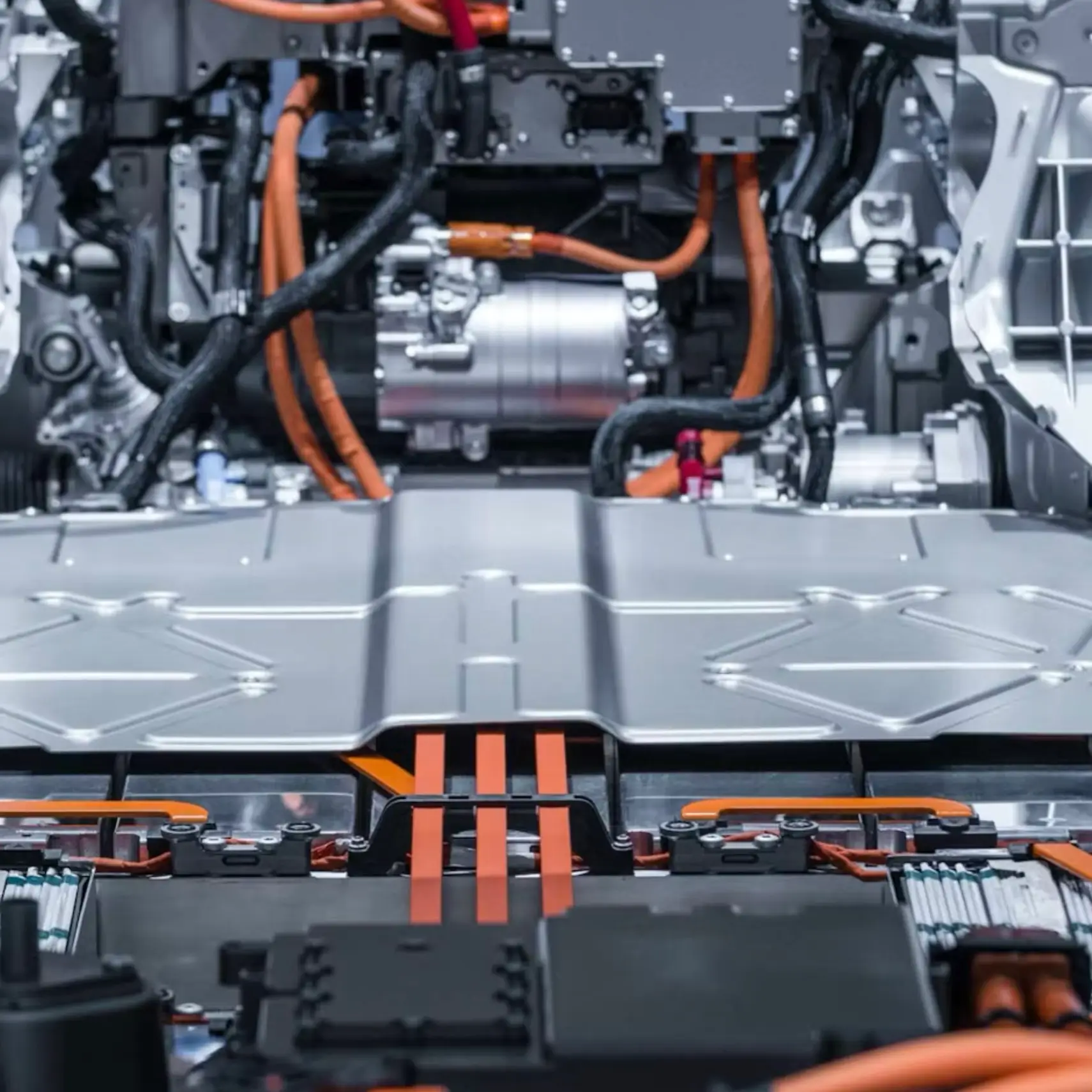

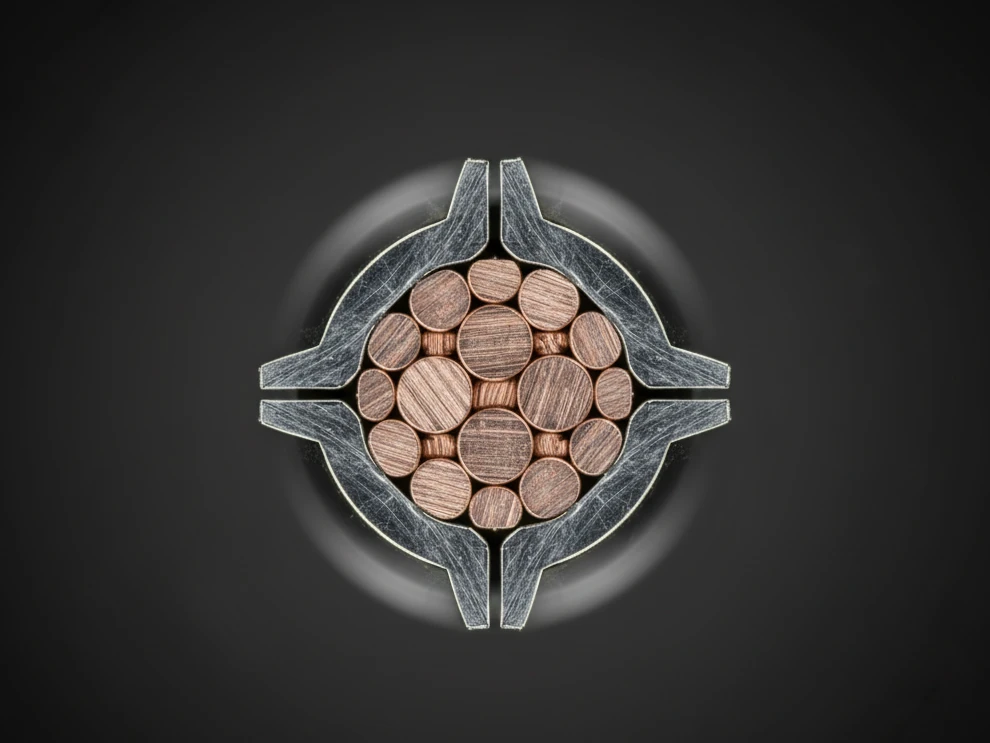

HV Shielded Bundle

High voltage harnesses with 360° shielding and HVIL integration for safety compliance.

Labeling & Kitting

Precise labeling and custom kitting services for easy installation and traceability.

Crimp Analysis

Microscopic crimp cross-section analysis ensuring optimal electrical and mechanical connections.

Test Setup

Automated test fixtures for 100% continuity and hipot testing with data logging.

Quality Control

Multi-stage quality inspection ensuring IPC/WHMA-A-620 compliance standards.

Typical Use Cases

Real-world applications across industries

AGV/Forklift LV Loom

Battery HV Sub-assembly

RV/Retrofit Loom Kit

Capability Boundaries

Clear capabilities and honest limitations

We Can Do

Boundaries / Needs Evaluation

Client Testimonials

Engineering teams share their experience

Supplier Quality Engineer

Tier-2 Lighting Module, Germany

"We needed an automotive wire harness partner that understands IATF and PPAP without adding layers of red tape. Their team delivered LV harness prototypes within 10 days — all with 100% continuity and hipot test reports."

Mechanical Engineer

EV Powertrain Startup, USA

"For our high-voltage battery harnesses, they aligned perfectly with our standards — ISO 19642 and USCAR requirements were clearly followed. The 3 kV hipot verification and 360° shield grounding were done exactly to spec."

Founder / CTO

Energy Storage & RV Retrofit, UK

"We appreciated the straight talk — they told us upfront what's in-house and what's third-party. Despite outsourcing complex overmold and vibration testing, they coordinated everything smoothly. One engineering contact managed both LV and HV harnesses across two factories."

Operations Manager

AGV / Forklift Integrator, Singapore

"We handle multiple low-volume vehicle programs, and their LV harness kits fit right in — each labeled, coiled, and kitted for our assembly lines. What impressed us most was the 100% continuity report matching our jig IDs."

Commodity Manager

Tier-2 Thermal Systems, USA

"They earned our trust with predictability and honesty. The quote came with a clear pricing ladder and transparent DFM notes. PPAP / IMDS support was project-based, executed through their HV-qualified factory."

About Our Engineering Workflow

Who We Are

We are a China-based Automotive Wire Harness Supplier partnering with vetted SME wire-harness factories. You get one engineering contact orchestrating multi-factory capacity, with transparent testing (100% continuity & hipot) and project-based compliance (IATF/PPAP/IMDS). We state clear capability boundaries and avoid over-promising.

Why Choose Us

How We Work

Our Clients

We typically serve Tier-2 module makers, EV/startup teams, and off-highway integrators needing custom LV/HV harnesses, branded connectors, traceable testing, and tight timelines.

Need a Pragmatic Quote?

Send your drawing/BOM—reply within 24h on business days.